- Home

- About Us

-

Products & Services

Hydroxyethyl methacrylate(HEMA)Hydroxypropyl methacrylate (HPMA)Hydroxyethyl acrylate (HEA)Hydroxypropyl acrylate(HPA)Methacrylic acid(MAA)lsobornyl methacrylate(IBOMA)lsobornyl acrylate(IBOA)Methyl methacrylate (MMA)P-Phenylenediamine(PPD) 4-Nitroaniline(PNA)Expandable MMA beadsEthyl Methyl Carbonate(EMC)Barrel industry productsButyl Acrylate (BA)

- Application

- News

- Honor

- Factory

- Contact Us

- HomeHome

- About UsAbout Us

- Products & ServicesProducts & Services

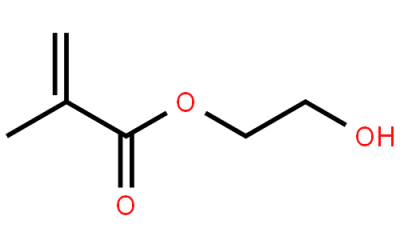

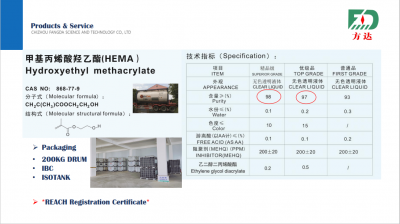

- Hydroxyethyl methacrylate(HEMA)

- Hydroxypropyl methacrylate (HPMA)

- Hydroxyethyl acrylate (HEA)

- Hydroxypropyl acrylate(HPA)

- Methacrylic acid(MAA)

- lsobornyl methacrylate(IBOMA)

- lsobornyl acrylate(IBOA)

- Methyl methacrylate (MMA)

- P-Phenylenediamine(PPD)

- 4-Nitroaniline(PNA)

- Expandable MMA beads

- Ethyl Methyl Carbonate(EMC)

- Barrel industry products

- Butyl Acrylate (BA)

- ApplicationApplication

- NewsNews

- HonorHonor

- FactoryStyle

- Contact UsContact Us

- 中文版

Fangda Chemical

Dedicated to producing new chemical materials

Fangda Chemical

Improve testing equipment and advanced production processes

Fangda Chemical

Pioneering · enterprising · innovative · pragmatic

Down

Hydroxyl monomer specialists, hand in hand with you for the future!

The company invested and built Chizhou Fangda Technology Co., Ltd. in October 2006, which is a national high-tech enterprise specializing.

-

66600m2

Factory footprint

-

2000

Quzhou Fangda Chemical was established in

-

70000mt

Annual output

The company mainly produces methacrylic acid, hydroxyethyl acrylate, hydroxypropyl acrylate, hydroxyethyl methacrylate, hydroxypropyl methacrylate, isobornyl methacrylate.

The first time to learn more about the latest news of Fonda Chemical, we will be happy to serve you!